The construction industry is undergoing a profound transformation, driven not just by innovative materials, but by powerful digital intelligence.

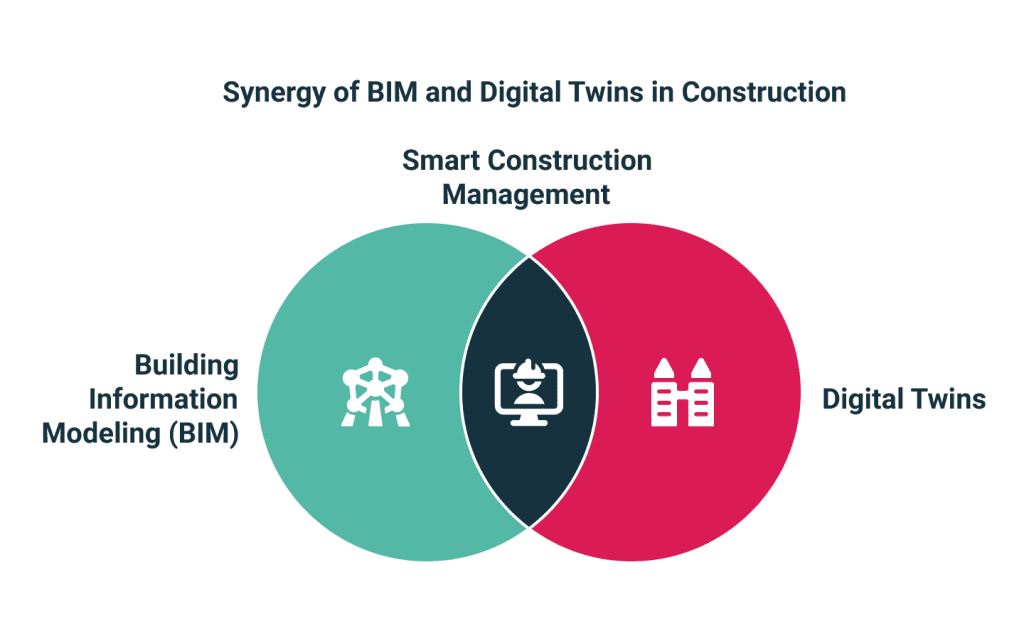

In a field often characterized by inefficiencies, delays, and miscommunication, tools like Building Information Modeling (BIM) and digital twins are enabling a smarter, more integrated way to plan, build, and operate. For complex, precision-sensitive projects such as mass timber and offsite construction, these technologies are rapidly becoming indispensable.

What Is BIM and How Does It Work?

Building Information Modeling (BIM) is far more than just 3D modeling. It’s a collaborative process that provides architects, engineers, contractors, and fabricators with a shared digital representation of a building’s physical and functional characteristics. Crucially, BIM involves a structured database of information beyond just geometry, allowing for intelligent analysis and coordinated workflows.

With BIM, teams can:

- Identify clashes before construction begins: Preventing costly rework and delays by detecting conflicts between different building systems (e.g., plumbing, electrical, structural).

- Simulate sequencing and logistics: Optimizing construction schedules and site movements for maximum efficiency.

- Automatically generate material takeoffs: Accurately calculating quantities of materials, reducing waste and improving procurement.

- Collaborate in real-time across disciplines: Ensuring all stakeholders are working from the most current and accurate information.

In timber construction, where components are often prefabricated offsite and need to fit exactly, BIM ensures that what’s built matches what was designed down to the millimeter. This precision is vital for seamless assembly.

What Is a Digital Twin?

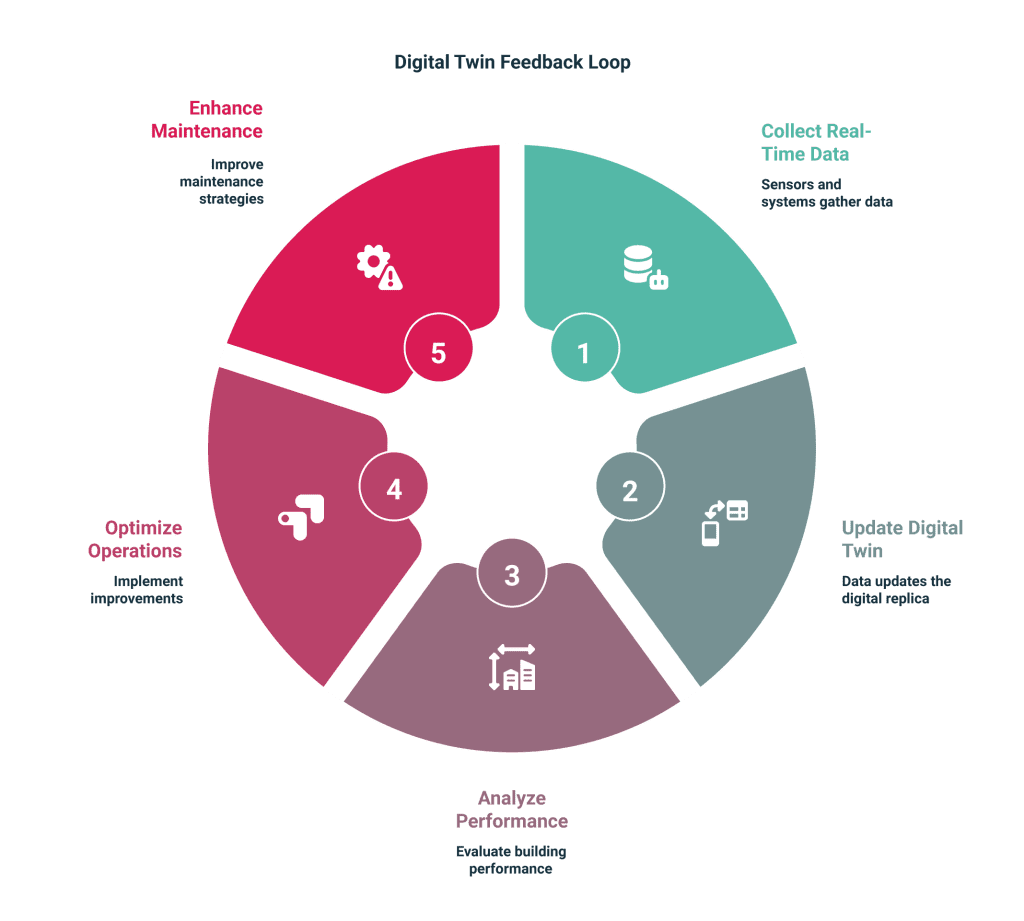

A digital twin is a live, dynamic replica of a building or asset, continuously fed by real-time data from sensors, building management systems, and other sources. While BIM primarily supports the design and construction phases, a digital twin truly comes alive after occupancy, creating a powerful feedback loop for ongoing operations, maintenance, and performance optimization.

In the context of timber or modular builds, digital twins offer immense value by:

- Monitoring humidity and structural behavior: Crucial for mass timber to ensure material integrity and long-term performance.

- Optimizing energy use and lighting: Adjusting systems in real-time based on occupancy, external conditions, and usage patterns.

- Predicting maintenance needs before issues arise: Shifting from reactive repairs to proactive, condition-based maintenance, extending asset lifespan and reducing downtime.

- Tracking progress and site conditions during construction: Bridging the gap between the design data in BIM and the real-world execution on site, optimizing workflows even before occupancy.

Digital twins offer long-term value by turning buildings into smart, responsive assets that continually learn and adapt, enhancing both performance and user experience.

Why This Matters in Mass Timber Projects

Mass timber projects demand exceptional accuracy. Fabricated panels and members are often cut to exact specifications before arriving onsite. A single miscalculation can lead to significant installation delays or require extremely costly rework.

With integrated BIM and digital twin workflows, teams can:

- Coordinate across trades earlier: Proactively resolving potential conflicts in the design phase.

- Reduce RFIs (Requests for Information) and change orders: Leading to smoother project delivery and fewer budget overruns.

- Accelerate permitting with detailed visualizations: Providing authorities with comprehensive, easily understandable project data.

- Enhance lifecycle performance monitoring: Ensuring the building performs optimally throughout its entire lifespan, from energy consumption to structural integrity.

In essence, these digital tools make it possible to treat construction as a high-precision manufacturing process, moving far beyond traditional guesswork.

From Reactive to Predictive: Building with Confidence

The future of construction isn’t just about speed, it’s about confidence.

Confidence that the structure will perform as intended. That the project team is aligned from design through operations. That timelines and budgets won’t spiral out of control.

With BIM and digital twins at the core of your project delivery model, you’re not just building smarter, you’re building better, more sustainably, and with unparalleled insight throughout the entire building lifecycle.

Want to Go Deeper?

Wondering how storytelling and smart marketing can advance offsite construction, mass timber, and sustainability in North America?

Whether you’re in AEC, sustainability, or shaping the built environment, we’d love to connect. Let’s talk – or explore BuildBetter.Marketing.

Structure needs story. Jib delivers.