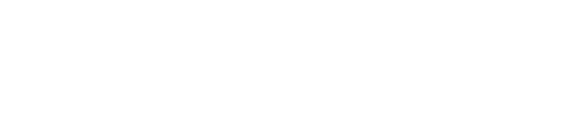

Why today’s contractors need a water-tight game plan for timber builds

Mass timber is rewriting the rulebook on sustainable construction, but it’s still wood. And when it comes to jobsite realities, there’s one immutable truth: wet timber spells trouble.

Whether you’re setting CLT panels in morning rain or framing through spring storms, protecting mass timber from moisture isn’t optional — it’s essential.

Why Moisture Matters

In mass timber systems, panels and beams often serve both structural and aesthetic roles. That means any swelling, staining, or mold risk can translate into costly rework or visual defects. The thicker the wood element, the harder it is for moisture to dry out, making trapped moisture a real risk.

According to WoodWorks, moisture content in panels can rise rapidly under exposure and may exceed 30% in extreme conditions, and once trapped, wood can’t easily dry from within. (WoodWorks | Wood Products Council)

In fact, a Salem, Oregon public works project used a presentation at a Mass Timber conference to showcase the damage possible when temporary protection fails. (International Mass Timber Conference)

That’s why contractors, fabricators, and architects are increasingly calling moisture protection from delivery through installation a non-negotiable discipline.

Proven Strategies & Reference Resources

Here are mass timber weatherproofing best practices and linkable references you can vet and adapt for your own builds:

| Strategy | Description | Reference / Resource |

| Factory-Applied Panel Protection | Request that CLT/glulam arrive with sealed edges or factory wraps that allow drying. | RDH’s Mass Timber Moisture Management Guide is a strong reference. (RDH) |

| Just-in-Time Delivery & Staging | Limit how long panels sit exposed; store off the ground; use breathable covers. | WoodWorks outlines strategies and the dangers of trapping moisture. (WoodWorks | Wood Products Council) |

| On-Site Temporary Roofing or Tents | Use modular rain tents, zippered enclosures, or shifting canopies over floors and walls to keep rain off during installation. | A case study on moisture management and protection strategies was presented in Mass Timber conference programming. (Center for Architecture) |

| Sealing Joints & Edges | Use peel‑and‑stick membranes, joint tape, or sealant at panel interfaces and exposed edges while working through the build. | VaproShield’s guide on timber moisture management covers detail-level strategies. (VaproShield) |

| Ongoing Moisture Monitoring | Embed sensors or use portable moisture meters to track wood dryness before covering or finishing. | The Mass Timber Moisture Management Guide from RDH includes guidance on monitoring and thresholds. (RDH) |

Mass timber is a premium product. Moisture management isn’t just about damage control — it’s about protecting your schedule and your reputation.

Site Supervisor, Boston Mass Timber Project

What This Means for Contractors

- Moisture protection must be a line item—plan for it, schedule for it, budget for it.

- Train crews from day one to view rain, staging, and movement as risk, not just delays.

- Do not assume panels can “self-dry” if saturated. Proactive protection is cheaper than repair.

- Talk with your supplier about panel treatments, wrapping, and recommended site protocols.

- Document your drying checks and moisture data, it’s defensible quality control.

Mass timber rewards those who are prepared. Plan early, protect often, and build with confidence.

Wondering how storytelling and smart marketing can advance offsite construction, mass timber, and sustainability in North America?

Whether you’re in AEC, sustainability, or shaping the built environment, we’d love to connect. Let’s talk – or explore BuildBetter.Marketing.

Structure needs story. Jib delivers.