From Waste to Resource – A New Vision for Buildings

Imagine if our buildings could be taken apart like LEGO sets and rebuilt into something new instead of ending up as rubble. This vision is at the heart of an emerging architectural trend: designing buildings for disassembly. Today, construction and demolition waste make up a colossal portion of landfills – over 40% of landfill content comes from building debris in some regions. In response, architects and builders are embracing “circular” design principles that treat buildings not as disposable, one-time structures, but as banks of materials that can be recovered, reused, or recycled at the end of a building’s life. The approach is gaining traction as a forward-thinking solution to the construction industry’s waste and resource challenges.

One high-profile example is the Paris 2024 Olympic Village, which was planned with its next life in mind. The complex of 82 buildings was constructed using modular elements, low-carbon materials, and parts designed to be dismantled after the Games. In fact, most materials and structures in the Olympic Village will be **temporarily installed and then redeployed, reused, or recycled once the athletes depart. Rather than creating a ghost town or heaps of waste, the project demonstrates how major developments can be conceived from the start for easy disassembly and post-Olympics reuse. This kind of thinking represents a dramatic shift towards a circular architecture mindset – one where building components live multiple lives and nothing of value goes to waste.

What Is Design-for-Disassembly (DfD)?

Design-for-Disassembly (DfD) means planning and constructing buildings in a way that they can be taken apart systematically in the future, in whole or in part, and their components recovered for reuse. In a traditional linear building process, materials flow one-way from production to construction to demolition (and landfill). DfD instead aligns with a circular economy, keeping materials in circulation. By definition, DfD involves anticipating the end of a building’s lifespan from the very beginning of design: every beam, panel, or facade is chosen and detailed so that it can be efficiently deconstructed and fed back into the “reduce, reuse, recycle” loop. In practical terms, designing for disassembly is like giving a building an “exit plan” – ensuring that when its current use ends, it can retire gracefully without turning into a pile of waste.

This concept, first explored in the 1990s, has only recently started entering mainstream practice. Cities such as London are even introducing policies to promote it – for example, the latest London Plan will require new developments to demonstrate how their components could be taken apart and reused down the line. The ultimate goal is that buildings become material repositories rather than dead-end waste: a steel beam or timber plank from one structure could be extracted and given a second life in another project, creating an endless cycle of building materials in use.

Key Principles of Designing Buildings for Disassembly

To design a structure that comes apart as neatly as it goes together, architects follow several core principles:

- Plan for Deconstruction from Day One: DfD starts in the early design phase by creating a deconstruction plan. This includes labeling and documenting all components and how they should be separated later, often with digital models or “material passports” to track each element. By anticipating a building’s disassembly instructions up front, designers ensure nothing is built in a way that prevents its future reuse.

- Select Materials Wisely: Materials are chosen not just for performance, but for their ability to be recycled or reused. DfD favors high-quality, non-toxic materials that can withstand being assembled and disassembled multiple times. It also means avoiding composite materials or permanent finishes that are hard to separate. Every material should answer the question: What will happen to this at end-of-life? If it can’t be reclaimed or repurposed, it’s rethought.

- Use Reversible Connections: One fundamental DfD strategy is to avoid glues, sealants, or welded joints that permanently bind materials. Instead, buildings are detailed like giant modular kits, using bolts, screws, clips, or interlocking systems so that parts can be taken apart with minimal damage. Accessible connection points (and even numbering systems to identify parts) make it easy to disassemble components with common tools, rather than resorting to jackhammers or wrecking balls.

- Design for Adaptability and Modularity: A building designed for disassembly often benefits from a modular design with standardized components. Standard sizing and modular units mean pieces can be swapped or replaced without custom fabrication. Moreover, separating major systems (structure, facade, interior partitions, mechanical systems, etc.) allows updates or replacements over time without tearing the whole building apart. This not only extends the building’s useful life but also makes eventual disassembly more straightforward, since components aren’t irreversibly tangled together.

- Document and Track Materials: Keeping an up-to-date inventory of materials in a building (often through Building Information Modeling and material databases) is also emerging as a DfD practice. This “material passport” concept means that decades later, owners or demolition contractors will know exactly what can be salvaged and how. It’s like giving each building a manifest for its next life.

By applying these principles, architects create structures that are ready for change. Such buildings can be more easily repaired, reconfigured, or ultimately deconstructed with far less waste. As one sustainability strategist quipped, it makes buildings a bit more like IKEA furniture – designed with the end assembly (and re-assembly) in mind.

Benefits of Design-for-Disassembly

Building for disassembly is fundamentally about cutting waste and conserving resources, but its benefits stack up in multiple ways:

- Dramatically Reduced Waste: Perhaps the most obvious advantage is diverting tons of material from landfills. When a disassemblable building comes down, far more of its components avoid the dump. This addresses a critical issue in an industry where most materials currently never return to the loop after a building’s demolition. Less construction debris means less land needed for landfills and less environmental harm from waste.

- Resource Conservation and Lower Carbon Footprint: Reusing structural elements, facades, and fixtures avoids the need to produce new materials from scratch. This translates to big savings in energy and emissions. Globally, construction is the single largest consumer of raw materials; DfD directly curtails the demand for new steel, concrete, glass, etc., by keeping existing materials in circulation. That reduction in “embodied energy” means lower carbon emissions associated with extracting, processing, and transporting virgin materials. In short, recycling a building can be far greener than building a new one. For example, Arup’s Circular Building prototype in London was designed for easy disassembly so its materials could be reused – a strategy that significantly minimized waste and environmental impact during its lifecycle.

- Cost Savings and Material Value: There’s an economic upside to all this as well. A building can be seen as a valuable store of commodities – steel, timber, bricks, fixtures – that retain value. If those assets can be harvested at end-of-life, the owner can recoup costs or even earn money by selling salvaged materials. High-quality steel beams, bricks, or hardwood flooring are worth real dollars on the resale market. As design-for-disassembly becomes more common, we may see deconstructed buildings become treasure troves of materials for new projects. One analyst noted that salvaging materials is akin to finding out “your old comic book collection is worth a fortune” – assets hiding in plain sight. Additionally, developers save on disposal fees and can avoid purchasing as many new materials for future builds.

- Extended Building Life and Flexibility: Even before a full disassembly, the DfD approach encourages designs that can be adapted and renovated easily. Because components can be removed without wrecking the whole structure, owners can reconfigure spaces or upgrade systems (like HVAC or facades) with less cost and waste. This adaptability means buildings can stay relevant for longer instead of being torn down when needs change. In a way, DfD can give a building multiple lives – either on the same site or in pieces at new sites – embodying a resilience and longevity that traditional construction often lacks.

All these benefits feed into the larger vision of circular architecture: an architectural ecosystem where materials perpetually cycle and the concept of “waste” is virtually eliminated. A recent thought leadership piece summed it up well – designing buildings with a graceful exit strategy ensures they leave behind assets, not debris.

Challenges on the Path to Circular Construction

If designing for disassembly is so beneficial, why isn’t every building already following DfD principles? The reality is, this approach still faces several challenges and barriers:

- Traditional Mindset and Practices: The construction industry has long optimized for upfront cost and speed. Demolition is fast and cheap; carefully deconstructing a building is still relatively labor-intensive. In the short term, it can cost more and take longer to build in a disassemblable way. Many developers default to business-as-usual methods, and convincing them (and their financiers) to invest in DfD requires demonstrating long-term savings that aren’t always immediately visible on a balance sheet. It’s a bit like convincing people to eat their vegetables – the payoff comes later. Overcoming the inertia of “this is how we’ve always built” will take education and proven success stories.

- Lack of Regulations and Incentives: Building codes and standards in many places do not yet account for or encourage design-for-disassembly. In fact, some regulations inadvertently discourage reuse – for example, strict code requirements can make it hard to re-certify reused structural elements, even if they are perfectly sound. This regulatory lag means architects and builders pursuing DfD are often doing so voluntarily, rather than to meet code. There are bright spots: a few cities have started adopting deconstruction ordinances (such as Portland, San Antonio, and Milwaukee) which require certain old buildings to be dismantled rather than demolished, to salvage materials. More government incentives – like tax breaks for reuse or credits in green building certifications – could greatly accelerate the adoption of circular practices.

- Uncertain Supply Chain for Reused Components: One practical hurdle is predictability of reclaimed materials. If you design a building hoping to source a lot of reclaimed components, it can be challenging to get consistent quality and quantity. Likewise, planning to reuse today’s building parts 30 years from now involves some guesswork: will those materials still meet future codes or find a market? This uncertainty can make developers nervous. However, as more projects document their material inventories and as marketplaces for reclaimed building parts mature, this should improve. The success of DfD ultimately relies on developing a robust ecosystem for reclaimed materials, from certification standards to resale platforms.

- Design and Documentation Effort: Practicing DfD requires extra effort from the entire design and construction team. Architects must detail buildings more meticulously, thinking through disassembly sequences and labeling parts. Contractors need new skills to assemble things in ways that facilitate future removal. This collaborative, systems-thinking approach is still new, and it demands greater coordination Upfrontr. There is also a knowledge gap – many architects and engineers simply haven’t been trained in DfD strategies yet. Closing this gap will require updated curricula in architecture/engineering programs and industry training on techniques and tools for circular design.

Despite these challenges, momentum is building. As more examples demonstrate that design-for-disassembly can be done economically and successfully, the industry’s comfort level will grow. Importantly, research is showing that if you factor in the salvage value of materials, deconstruction can be cost-competitive with demolition – especially if those materials have good market value to offset labor costs. In the long run, the economics may well flip in favor of DfD, especially as natural resources become scarcer and disposal costs rise.

Pioneering Projects Embracing Design-for-Disassembly

Many forward-thinking projects around the world are already showcasing how design-for-disassembly works in practice – from temporary Olympic venues to experimental green buildings:

- Olympic Venues with Second Lives: The Olympic Games, notorious for leaving behind massive but short-lived structures, have started to adopt DfD principles to avoid wasteful legacies. We saw how the Paris 2024 Athletes’ Village was built to be transformed after the event, with many parts slated for dismantling and reuse. Similarly, the Rio de Janeiro 2016 Olympic Handball Arena (dubbed the “Future Arena”) was designed as a modular structure that could be taken apart post-Games. Once the cheers faded, the arena’s components were in fact dismantled and transported to build four new public schools in Rio – a brilliant repurposing of material that gave the arena a meaningful afterlife as much-needed educational facilities. These examples show how designing with an exit strategy can turn a temporary venue into a lasting resource for the community, instead of a costly white elephant.

- Prototype Circular Buildings: Outside of sporting events, architects and engineers have been testing DfD ideas in pilot projects and pavilions. A notable example is The Circular Building in London, a small demo structure created by Arup for the 2016 London Design Festival. The Circular Building by Arup was a prototype assembled from pre-fabricated panels with reusable connections, intended to be easily disassembled and reassembled elsewhere. Its designers pushed the boundaries of modular construction – the building featured a demountable wall system with clamp fixtures and a recycled steel frame, all aimed at showing that a low-waste, “flat-pack” architecture is possible. In the end, the entire pavilion could be taken apart in mere days, with its materials earmarked for reuse. Another groundbreaking project is NASA’s Sustainability Base in California, an ultra-sustainable office building designed by William McDonough + Partners. NASA incorporated DfD thinking so that even this permanent facility can be uncoupled in the future – its component parts (from steel to drywall) are planned to be recoverable when the building eventually reaches end-of-life. By building as if they might one day unbuild, these projects serve as living laboratories for circular design. They demonstrate that with ingenuity, buildings can be both high-performance and impermanent by design, ready to feed a reuse economy.

Ouroboros Deconstruction: Reuse in Action on the Ground

While architects experiment with design techniques to make future buildings more circular, some companies are tackling the millions of buildings already standing – or coming down – right now. Ouroboros Deconstruction is one inspirational example of putting the reuse philosophy into practice today. Founded in Toronto by Meredith Moore, Ouroboros is a woman-led company that specializes in sustainable deconstruction as an alternative to conventional demolition. The very name “Ouroboros” refers to the ancient symbol of a snake eating its tail, signifying eternal cyclic renewal – a fitting metaphor for their mission to keep construction materials in continuous circulation.

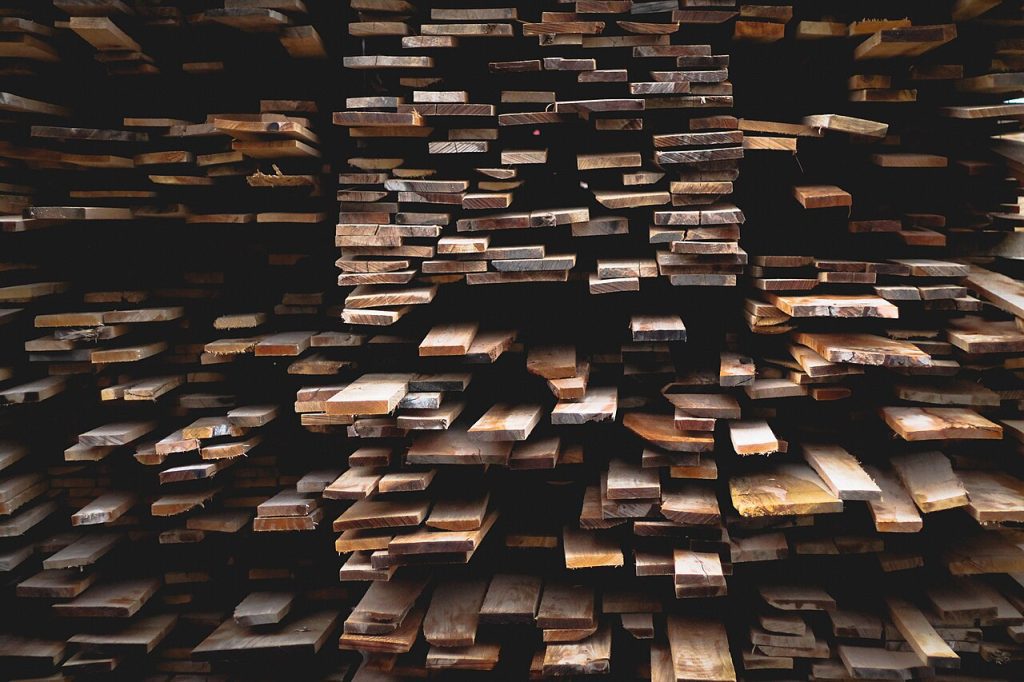

Deconstruction salvages valuable materials – for example, here stacks of old lumber are reclaimed and sorted for resale instead of being sent to a landfill. Ouroboros’ team uses “gentle removal” techniques to carefully dismantle buildings, essentially construction in reverse, in order to salvage materials destined for the bin. Instead of smashing walls and bulldozing structures into mixed debris, they extract elements one by one: hardwood flooring, framing lumber, bricks, cabinetry, windows, antique fixtures – you name it. “I understand that certain structures have to come down or be updated,” Moore says, “but they are rich in history and value, and then we are putting them right in the landfill when items should be salvaged and reused in new applications. We should strive for the highest and best use of these materials”. This ethos drives Ouroboros to recover as much as possible from every teardown project.

In practice, Ouroboros Deconstruction has turned what used to be the most wasteful phase of a building’s life (demolition) into a source of locally harvested materials. They have established warehouses totaling thousands of square feet to store salvaged goods – from century-old wooden beams to vintage light fixtures – and make them available at affordable prices for new construction or interior design projects. By creating a supply chain for reclaimed materials, they lower the barrier for others to incorporate reused elements in their buildings. Each home deconstructed by Ouroboros yields an Aladdin’s cave of architectural components that can add character to a new space while reducing demand for new lumber or manufactured products. As one article noted, project by project, Ouroboros is helping normalize deconstruction and showing that even our city’s older buildings “are not trash – they’re full of treasure” waiting to be saved.

The work of companies like Ouroboros directly supports the broader trend of circular architecture. They provide the on-the-ground means to complete the circle: taking apart buildings in a way that materials actually get a second life. Design-for-disassembly in new construction goes hand-in-hand with deconstruction services for existing buildings – together they form a closed-loop system. Ouroboros’ “full-circle approach to material recovery” ensures that valuable resources bypass landfills and are returned to the materials ecosystem. In doing so, they also preserve a piece of local heritage (think of those beautiful old-growth wood floors or vintage hardware that would otherwise be dumped). It’s a powerful proof-of-concept that with creativity and care, we can construct (and deconstruct) a built environment that continuously renews itself, just like the Ouroboros symbol.

Toward a Circular Building Future

Designing buildings for disassembly represents a profound shift in how we think about architecture – from a disposable product to a circular, living system. What was once a niche experimental idea is rapidly evolving into a practical philosophy for sustainable development. With growing pressure to cut carbon emissions and reduce waste, the timing is ripe. We are likely to see more building codes recognize material reuse, more developers factoring salvage value into their pro formas, and more creative design solutions that make disassembly elegant and economical. It’s a future where every building comes with an “exit strategy” – not as a doom-and-gloom footnote, but as a thoughtful plan for regeneration.

In this future, an old office tower might become a “mine” for new projects, its steel and glass reincarnated in a dozen new buildings. Companies like Ouroboros Deconstruction are demonstrating today that even our past construction can feed into this regenerative cycle, one salvaged beam at a time. The transition won’t happen overnight, but the direction is clear: the circular architecture approach is moving from theory into mainstream practice, supported by both top-down policies and bottom-up pioneers. Embracing design-for-disassembly is ultimately about rethinking value – recognizing that our buildings are not mere disposable shells, but repositories of materials and history that can continue to serve society in new forms. In the long run, designing for a building’s graceful disassembly is just smart, responsible design. It ensures that when a structure’s story ends, the story of its materials continues, contributing to new creations instead of becoming waste. That idea – building with the end in mind – is how we construct not just structures, but a truly sustainable future.

Wondering how storytelling and smart marketing can advance offsite construction, mass timber, and sustainability in North America?

Whether you’re in AEC, sustainability, or shaping the built environment, we’d love to connect. Let’s talk – or explore BuildBetter.Marketing.

Structure needs story. Jib delivers.